Extrusion lines for the construction sector

Performance and innovation

For over 40 years, Corelco has been supporting the construction sector by offering high-performance extrusion lines that keep pace with technical developments and new standards. Our equipment enables us to produce high-quality electrical and sanitary ducting, guaranteeing reliability, speed and compliance with market requirements.

Market overview

Electrical corrugated pipe

The first corrugated pipes appeared on the market in the early 50s. Produced in PVC, they were immediately accepted and found themselves in competition with smooth pipes. However, corrugated pipes quickly became the preferred choice, as they offered a number of advantages over smooth pipes.

Over the past 70 years, electrical corrugated pipes have come a long way and are now marketed in a variety of forms.

First and foremost is the material: initially produced in PVC, which was state-of-the-art at the time, they are now produced in polyolefin (PP - PE) depending on the country and its standards.

The electrical market range

It has a diameter range from 16 to 63 mm, depending on the number and type of conductors to be protected. Ø 16-20-25-32-40-50-63 mm

It can be flame-retardant. It is packaged in coils of 25-50-80-100 metres. Depending on market segmentation, it can be manufactured as the following products:

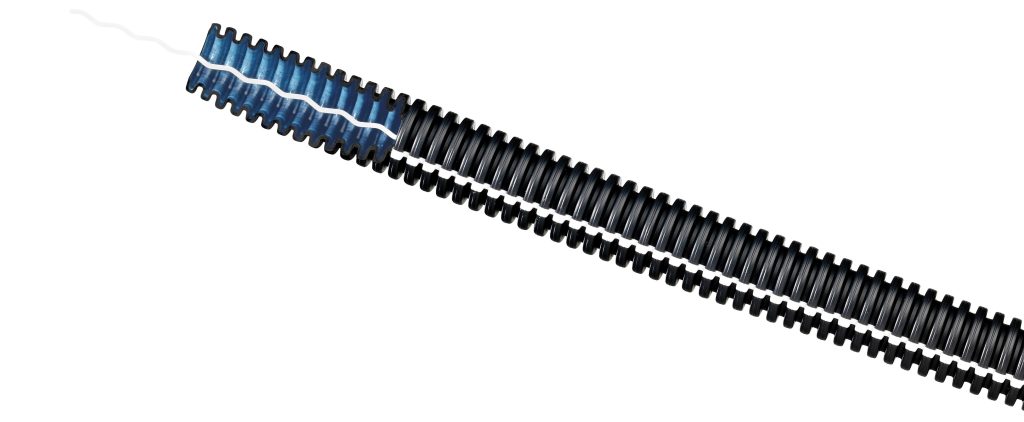

Basic pipe with pulling wire or needle puller

It meets market demand while complying with current norms and standards

Premium pipe

It creates added value and offers a real advantage with its low friction inner layer, which reduces pulling effort by 70%

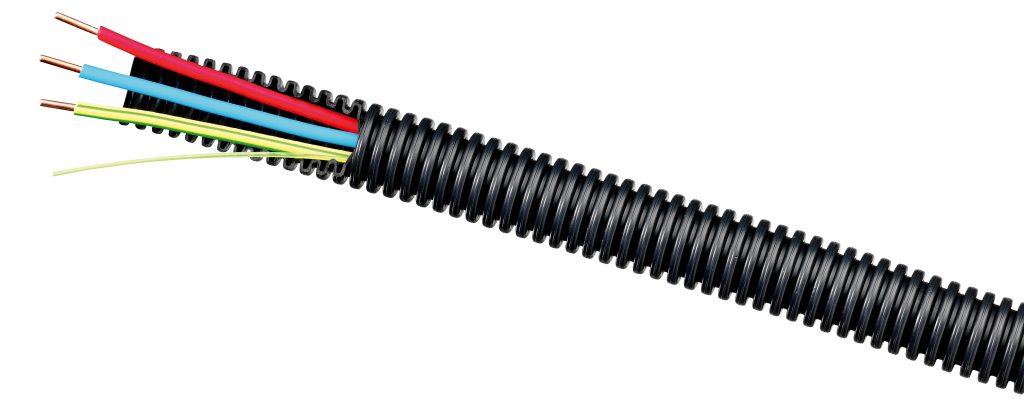

Pre-wired pipe

Extruded around electrical wires, it saves installers a considerable amount of time. Since Corelco launched this product in 1993, pre-wired pipes have steadily gained market share in a large majority of countries

Focus on pre-wired pipes

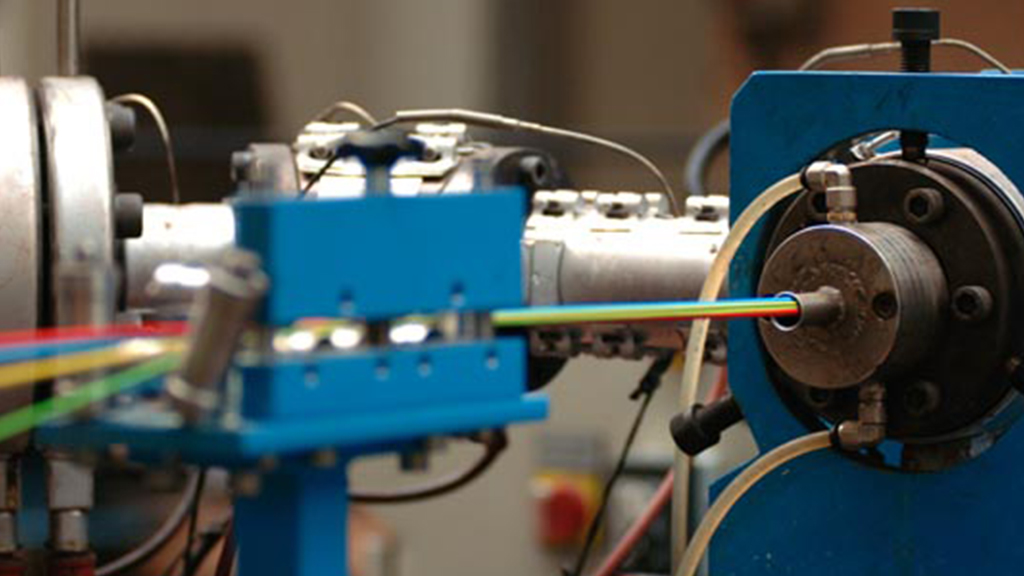

Produced in-line, the corrugated pipe is extruded around the electrical wires. It is mainly characterised by diameters of 16-20-25 mm, although the process has no production limits other than the fill rate.

The advantages of pre-wired pipes

For producers, users and distributors

- Saves time, reduces installation time

- Saves manpower, as only 1 person can work on the site

- Saves space, avoids double storage

- Increase in value

- Reduces the impact of transport costs

- Controlled process (1993) offering ever expanding possibilities

- Extended range, number and type of conductors, HO7VU, HO7VK, data cables, alarm, etc.

Since 1993, when Corelco invented the process - a world first - pre-wired pipes have been evolving and steadily taking market share from empty pipes.

Sanitary corrugated pipe

Sanitary pipes began to be used on building sites in the 90s. With the development of PER (cross-linked polyethylene) pipes to replace copper pipes, the sanitary corrugated pipe has found its place as a cylinder. It is now a must-have and is marketed in a variety of forms.

First and foremost is the material: depending on the construction of the PER pipe, it may be made of polyethylene or polypropylene.

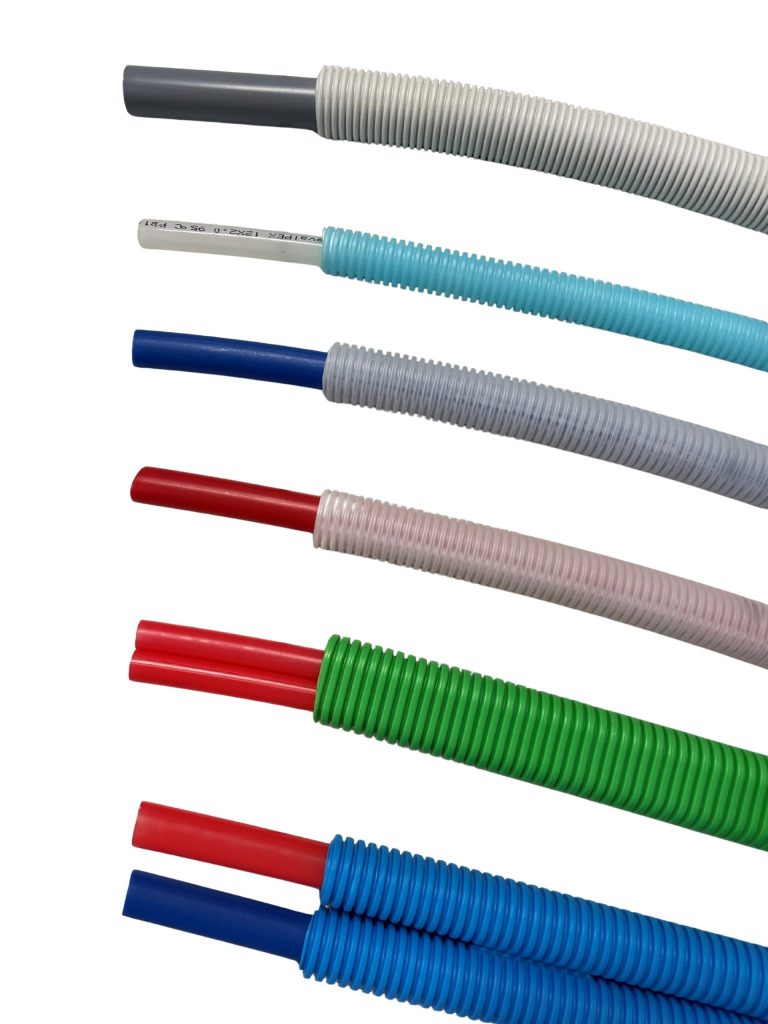

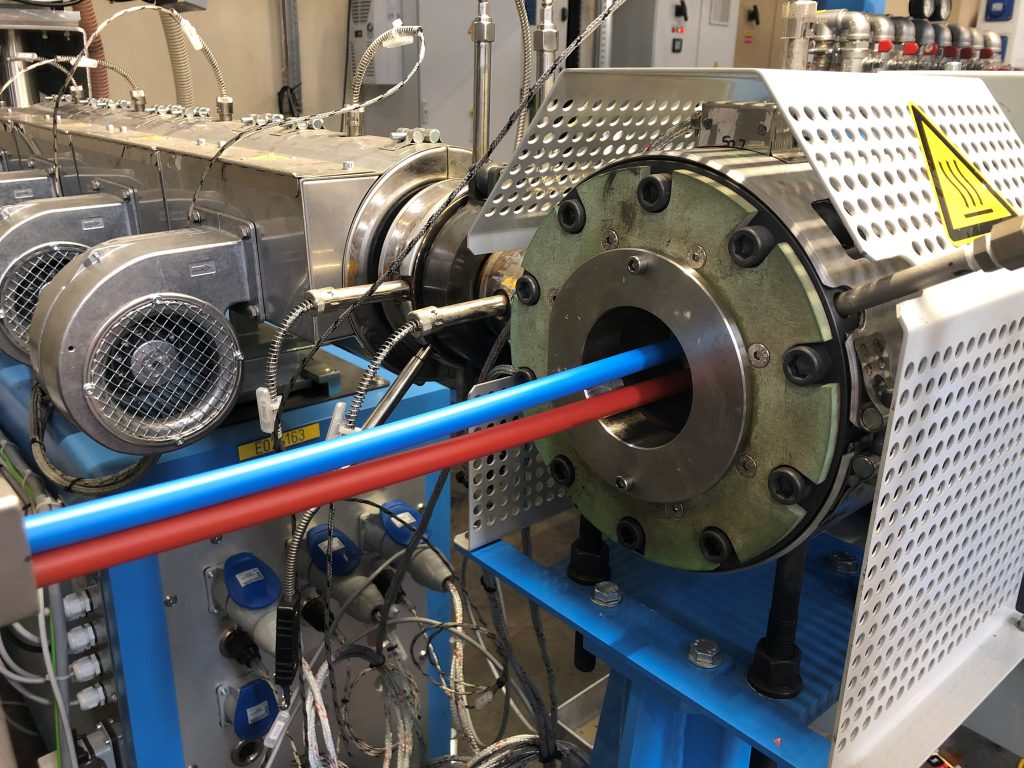

It can be produced empty or pre-tubed, with the sanitary pipe extruded around the PER pipe.

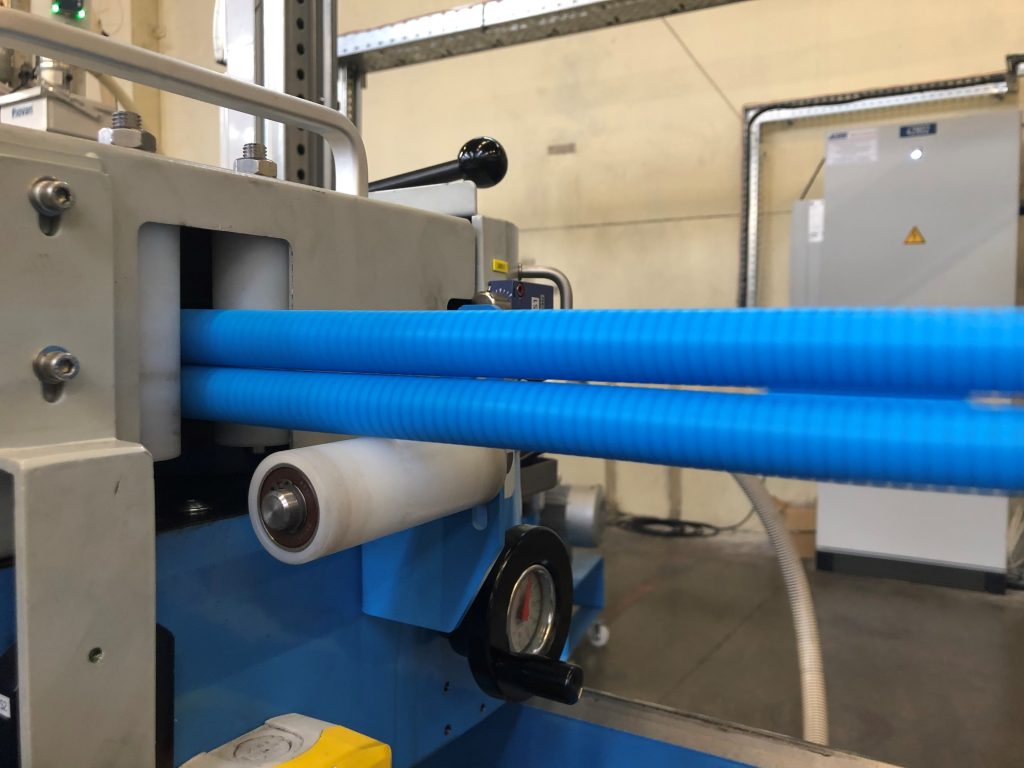

It can be produced in Mono or Duo versions. The Duo version allows you to connect hot and cold water simultaneously, using just one coil.

Pre-tubed pipe

Produced in line, the corrugated pipe is extruded around the sanitary pipes, which can be produced using a variety of processes: PERa - PERb - PERc - PERT - multilayer pipe with aluminium core.

- Mono pre-tubed pipe

- Duo pre-tubed pipe

The advantages of pre-tubed pipes

For producers, users and distributors

- Saves time, reduces installation time

- Saves manpower, as only 1 person can work on the site

- Saves space, avoids double storage

- Complete range, PERa, PERb, PERc, PERT, PER/AL/PER

- Increase in value

- Reduces the impact of transport costs

- Controlled process (1997) offering ever expanding possibilities

Since 1997, when Corelco created its first pre-tubed line, the pre-tubed pipe has been evolving and is steadily gaining market share over empty pipes.

The advantages of corrugated pipes over smooth pipes

The direct competitor of the corrugated pipe or priming tube (as it is called in certain African or Maghreb countries) is the smooth pipe.

The smooth pipe is sometimes preferred to the corrugated pipe for the wrong reasons.

Some people think that electrical wires slide more easily in the smooth pipe, and believe that the corrugations may block the wires.

The laws of physics don't lie!

As the inner surface is smooth, it creates continuous contact with the wires, creating friction during pulling, whereas the corrugated pipe has point contact between the wires and the bottom of the corrugation, creating less friction.

The pipe's corrugations give it rigidity and flexibility, offering a much smaller bending radius than a smooth pipe.

The standard name for the electrical duct is "Corrugated, Transversely Curvable, Insulating Conduit".

With the same diameter and crush resistance, corrugated pipes are twice as light as plain pipes.

What are the benefits?

- Less material with the same strength => Lower production cost

- Smaller bending radius => Larger load quantity => Lower transport costs

- Greater flexibility => Reduced installed footage

Flexible & rigid at the same time!

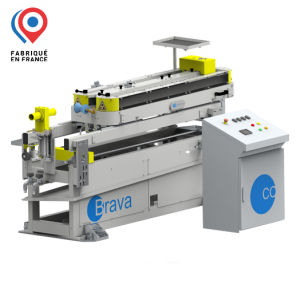

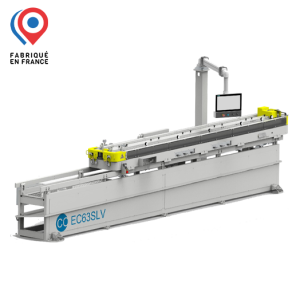

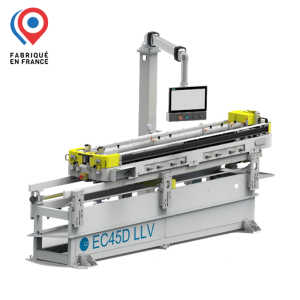

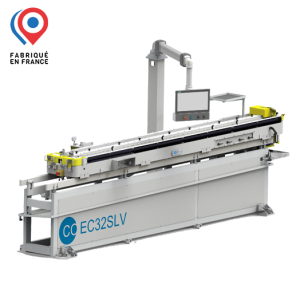

Reliability and productivity at the heart of our solutions

Our extrusion lines are designed to maximise profitability and productivity:

- Vacuum technology with indirect cooling for optimum control and reduced maintenance

- Fast, flexible production

Need a high-performance extrusion line for the construction sector?

Contact us for a personalised study and find out how Corelco can optimise your production!