Netting Lines

Corelco > Netting Lines

Equipment for plastic netting extrusion lines

Essential equipment for high-performance extrusion!

Corelco offers a complete range of line components and follow-on equipment designed to ensure smooth, efficient and optimised production. Our equipment integrates perfectly with your flat or tubular plastic netting extrusion lines, ensuring precision, productivity and reliability at every stage of the process.

Essential equipment for quality extrusion

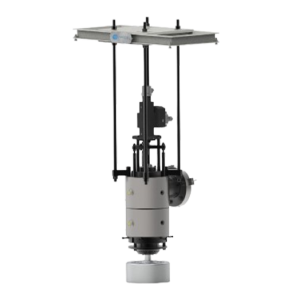

- Extrusion heads: Single or double flow, they guarantee even distribution of the material for consistent quality.

- Tools: Adapted to the different shapes and sizes of wire mesh, guaranteeing a precise, compliant end product.

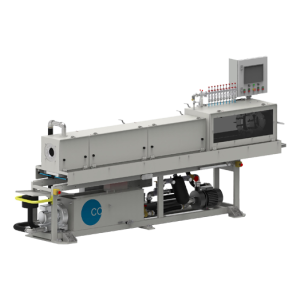

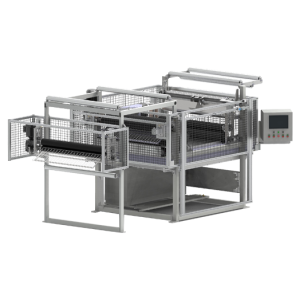

- Profile Generator: Single or multi-profile, it ensures precise, continuous shaping of the netting structure.

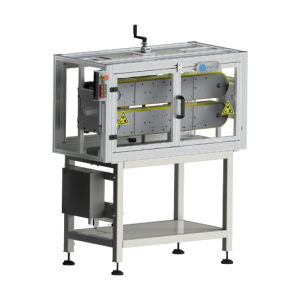

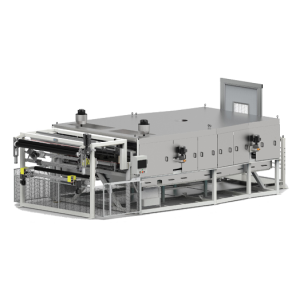

- Machine Direction Orientation: The longitudinal molecular orientation of the netting greatly increases its tensile strength and reduces its weight per metre.

- Transverse Direction Orientation: The transverse molecular orientation of the netting greatly increases its tensile strength and reduces its weight per metre.

- Cooling baths: Guarantee rapid stabilisation of the material for optimum quality.

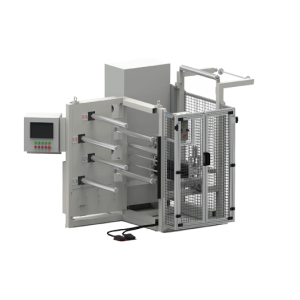

- Semi-automatic coilers: Ensures efficient, careful packaging of rolls of netting, winding at constant tension.

Transform your plastic netting production with Corelco!

With more than 40 years of expertise, Corelco is your partner for high-performance, made-to-measure extrusion solutions for tubular or flat netting. Contact us today for personalised support and study of your project!

Do you have a project? Contact us for a tailor-made solution!