Description

Speeds given for production Ø20 60 g/m 750N PP

With cooling water 6-8°C 3.5b

And a cooling bath

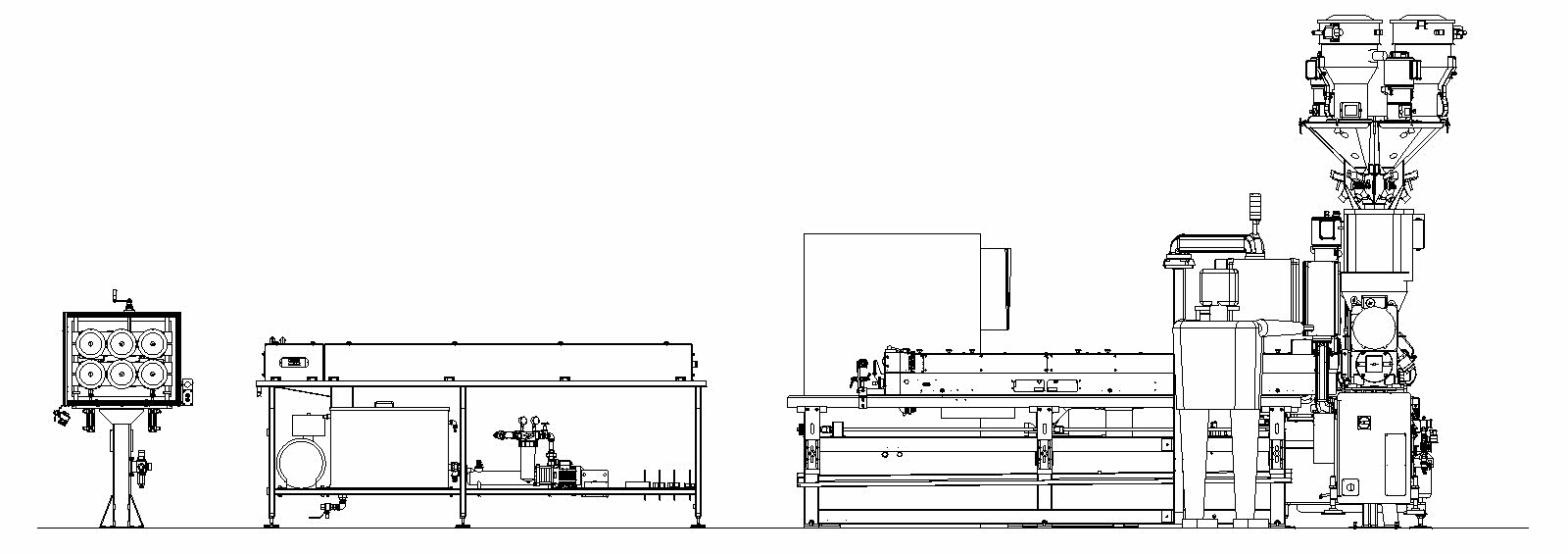

Typical line composition

- Extrusion head TE30/TP75/DT101

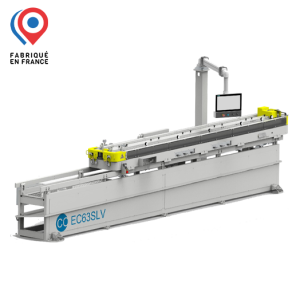

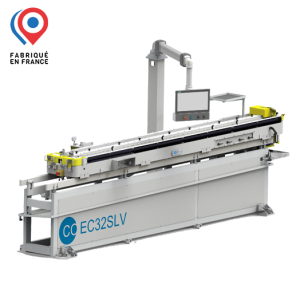

- Corrugator, EC45D LV - EC45D LLV - EC45D SLV

- Moulds 45V

- E200 vacuum pump

- Cooling bath 135X -138X

- Wheeled haul off 1011

- Wire feeding device 1040

- Pre-wired unit

- Pre-tubed unit

- Operator interface

Integration

- Extruder & Co-extruder

- Gravimetric colourer and doser

- Coiler

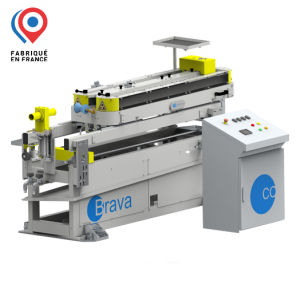

Dedicated to the pre-tubing process, but also to complement the range

- Siemens PLC

- ColourTouch line control 12/15/19

- Production parameter monitoring

- Water cooling and vacuum

- Automatic rear curves

- Anti-return system

- Remote connection via modem

- Access to production status

- OPC UA server

- Interconnection of emergency stops

ServiCE +

- Equipment for standards testing

- Know-how FORMULATION

Do you have a project? Contact us for a tailor-made solution!

Corelco offers you a complete, high-performance and scalable solution to optimise your production of electrical corrugated pipes and tubes.