Description

Speeds given for production in double wall HDPE

Ø200 1350 g/m

With cooling water 6-8°C 3.5b

And a cooling bath

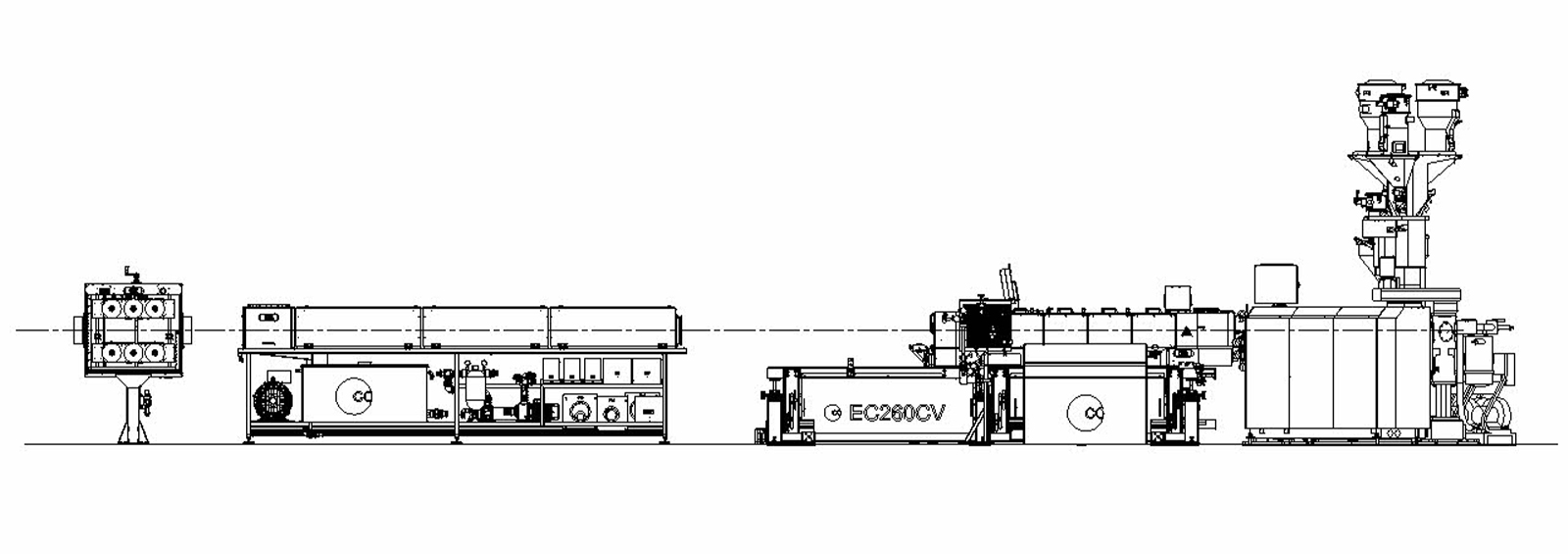

Typical line composition

- Extrusion head SP02/DP02

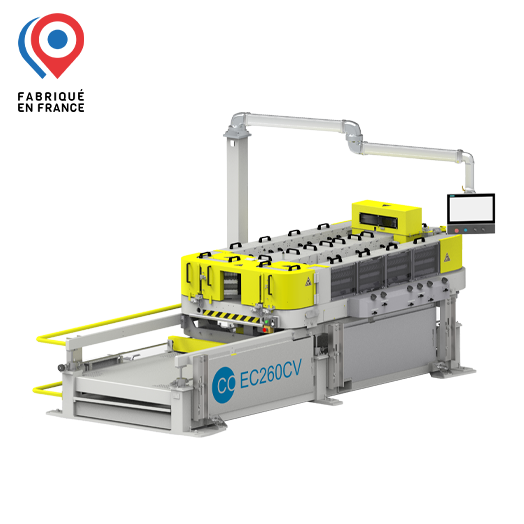

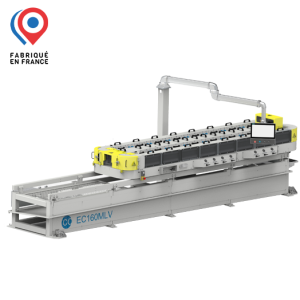

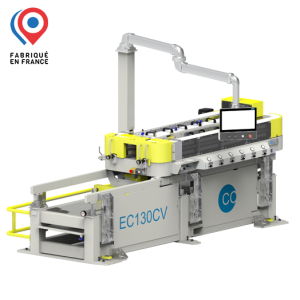

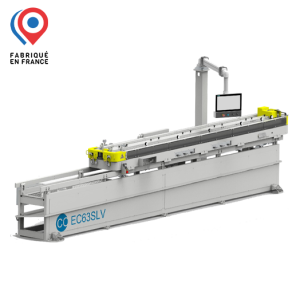

- Corrugator, EC260C - EC260L - EC260LL

- Moulds 260V

- E300 vacuum pump

- 137X cooling bath

- Wheeled haul off 1017

- Wire feeding device 1040

- Operator interface

Integration

- Extruder & Co-extruder

- Gravimetric colourer and doser

- Coiler

Ideal for Ø63 to Ø250 mm double wall pipes

- Siemens PLC

- ColourTouch line control 12/15/19

- Production parameter monitoring

- Cooling and vacuum

- Automatic rear curves

- Anti-return system

- Remote connection via modem

- Access to production status

- OPC UA server

- Interconnection of emergency stops

ServiCE +

- Equipment for standards testing

- Know-how FORMULATION

Do you have a project? Contact us for a tailor-made solution!

Corelco offers you a complete, high-performance and scalable solution to optimise your production of electrical corrugated pipes and tubes.